Optimal Use of Natural Resources, Oil Shale and Phosphates

The combination of oil shale with plastic waste in the pyrolysis process enables the treatment of plastic waste on the largest scale in Israel. The oil shale in Mishor Rotem, far from population centers, is located near the ground and can allow for open mining without the need for hydraulic fracking, underground heating or production wells.

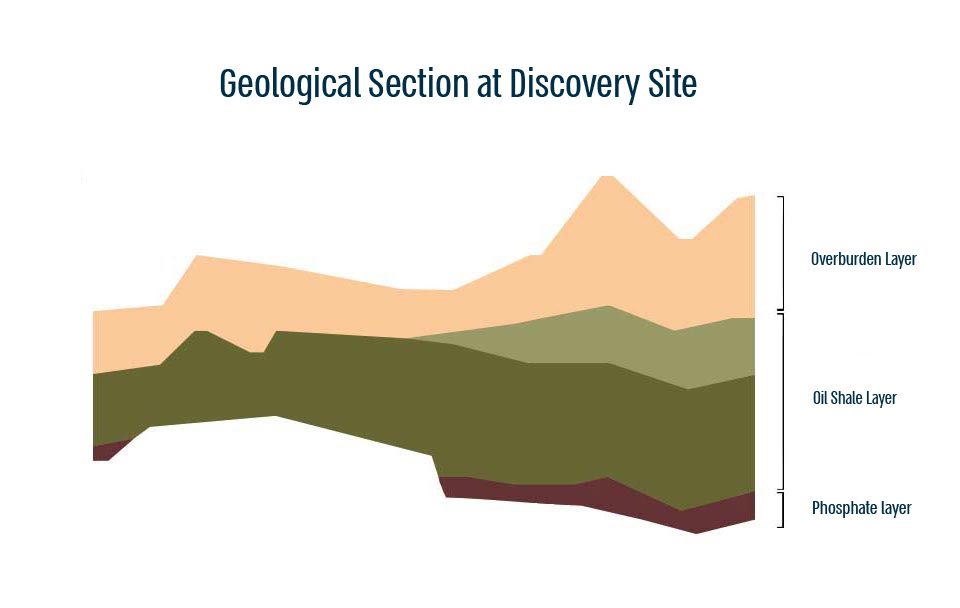

Open-pit mining of oil shale is currently executed by the company that mines phosphates in Mishor Rotem. The oil shale layers are overburden waste in the mining of phosphates, layered under the shales. Combined oil shale and phosphate mining will lead to maximum use of resources, reduction of emissions as compared to mining separately, prevention of self-combustion risks for the mined oil shale, and reduction of the need for oil shale mining in another area.

REM’s recovery process includes mining oil shale from an

open-pit mine at shallow depths, transferring the oil shale to the production plant and processing it together with plastic waste in enclosed and monitored facilities. The oil shale ash generated in the process will be used as a stream of heat-carrying solids in the process and then mostly transferred to finished mining pits as part of the site restoration stage.